The Buzz on Digital Printing

The Buzz on Digital Printing

Blog Article

The 9-Minute Rule for Digital Printing

Table of ContentsSee This Report about Digital PrintingNot known Incorrect Statements About Digital Printing What Does Digital Printing Mean?

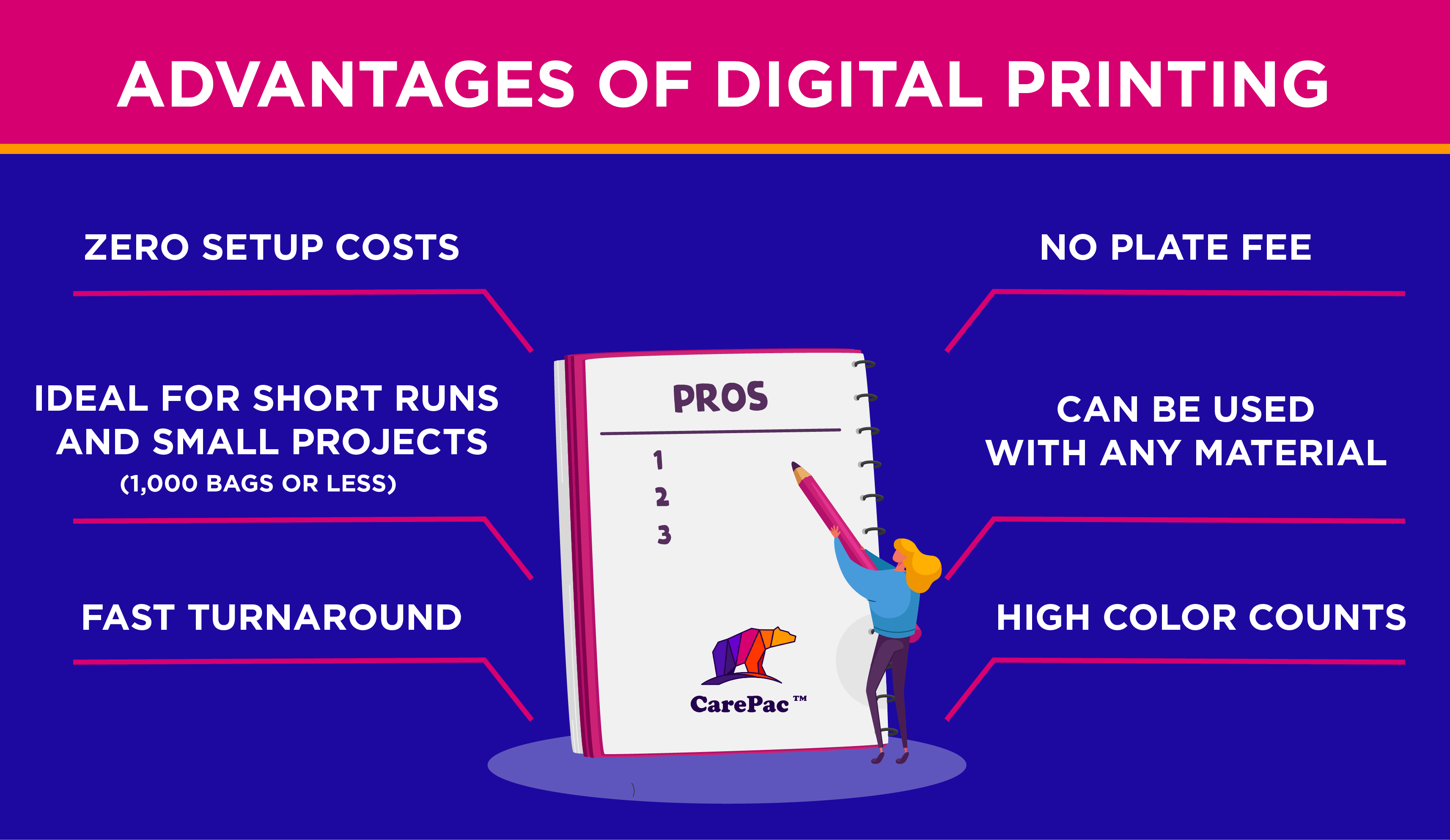

The fluid ink sticks to the substrate with an electrostatic charge, guaranteeing dynamic colours and sharp information. Digital printing additionally calls for marginal configuration. Modern lithographic modern technology has lowered configuration times to around 15 mins, digital printing still leads to ease with its near-instant readiness. Additionally, digital prints dry promptly, unlike lithographic prints, which call for 2-3 hours to dry. This removes smudging dangers and the requirement for drying out racks. Here are the vital means in which digital printing sustains greener techniques: Among the considerable ecological benefits of electronic printing is lowering waste. Standard printing techniques, like lithographic printing, usually waste significant amounts of paper and ink throughout the configuration stage. Digital printing removes the requirement for plates and various other consumables, decreasing waste throughout the manufacturing process. Several of one of the most usual applications consist of: Digital printing is excellent for creating calling card, leaflets, posters and various other marketing products. It permits fast turn-around times and cost-efficient manufacturing, particularly for services with smaller print runs. Digital printing is progressively made use of in the packaging industry to develop special, custom-designed product packaging.

Digital printing presses remove the requirement for these plates, substantially decreasing setup prices. Digital printing machine can incorporate variable information right into your prints, which permits very individualized marketing materials (Digital Printing). By individualizing your advertising and marketing materials, you can boost involvement with prospective clients and boost the opportunities of converting them into real clients

Digital printing presses offer outstanding shade consistency and accuracy, resulting in higher top quality prints. With electronic printing, you can be sure that the color of your prints will certainly be regular from one print work to the next. A number of years earlier, lots of customers did decline direct-injection digital printing since the high cost. The acquisition expense of a set electronic printing tools goes to the very least 150%of the standard printing and dyeing devices, which enhances the.

Some Of Digital Printing

For that reason, printers need to use a lot more fluid inks to More Info prevent nozzle clogging and printhead failing. In order to stop rust of the nozzle, the ink for electronic printing is more costly than the ink for standard printing, and additional ink filtration is required during the printing process. Additionally, the benefit of electronic inkjet printing is noticeable just when using inks with a huge color gamut. The digital inkjet printing machine virtually realizes the automatic control process. In electronic inkjet printing, the pattern is directly printed on the textile, removing home plate making in rotating screen printing. It not just saves the useful time of plate making, however likewise conserves the additional price of plate production. At the very same time, more and extra brands are now increasingly more approving of paying higher expenses for faster shipment, such as supplying a set of textiles within a week or perhaps 3 days, instead of weeks and months - Digital Printing. Yes, are much more pricey than typical printing inks, however the electronic printing process Digital Printing can conserve ink intake.

Today, the electronic direct-injection printing machine has actually gone from proofing to the phase of medium-sized and large-sized manufacturing. The digital direct-injection device has experienced the promo duration and went into the growth and maturation period. Both printing houses and brand owners are mindful of the advancement possibility of digital printing, and want to increase investment in digital printing. The print top quality can in some cases even competing that of balanced out printing. Digital printing is a lot more cost-effective for brief print runs because it calls for much less pre-press activities and much less arrangement than countered printing. If a mistake in offset printing is not caught before the plates are made, it will certainly be really expensive to make new ones. While everyone best regards really hopes that errors will certainly be stayed clear of, it is sensible to plan for their prospective improvement. Furthermore, its accuracy is extremely high. This guarantees uniformity in look across the board, minimizing the possibility that any type of item will need to be thrown away as a result of defects. Making sure the plates are in area, the ink secret is adjusted, and all the required adjustments have been made is a lengthy procedure when balanced out printing. Reduced pre-press steps mean less time is needed to set up the press. This leads to a marked velocity of turn-around time. When you require printed products swiftly, this is an excellent option. Digital printing can be a lifesaver when you obtain an order at the last min.

Variable data printing, such as straight mail with customized codes and addresses, is preferably matched for digital printing. Digital fast printing just requires four steps of style, evaluation, printing and binding to get every little thing done. Digital fast printing has an unmatched advantage: print on go now demand.

Report this page